SUMMARY

CFD is increasingly used in the food industry to optimize processes like drying, cooking, and cold storage, improving product quality and efficiency. By simulating airflow, heat transfer, and contamination risks, CFD helps design better equipment, like ovens and chillers, and enhances processes like sterilization.

INDUSTRY

Food Engineering & Processing

RESOURCES

Computational fluid dynamics has recently become a crucial tool for engineers to model industrial processes, conduct comprehensive engineering analyses and design more efficient production lines. Utilization of CFD has been beneficial by minimizing the endeavor for time and source consuming experimentations. Although many challenges are faced in representation of analytical models with accurate assumptions and approximations, recent advances in the numerical solution techniques has enabled the adoption of CFD as a reliable engineering tool in the food industry as well. Industrial processes such as drying, cooking,mixing, sterilizing and cold storage for preservation are thoroughly related to CFD and widely used in the food industry in order to improve the quality and shelf life of foods and beverages. In addition, utilization of CFD makes it much easier to respond to market demands, as it minimizes the endeavor put into cumbersome analysis whilst developing new processing strategies [1].

Unlike most of the other industries, it is essential to maintain the air quality and thermal conditions inside the food processing facilities at certain, optimized levels, since there exist crucial risks such as contamination of products due to existence of microorganisms.Besides, it is required to maintain a low air temperature around the product whilst keeping the temperature inside the facility at a comfort level to ensure convenient working conditions. Hence, it is a difficult challenge to render the behavior of air at predetermined conditions. Combining experimental techniques with CFD, airflow inside the facility can be studied and the ventilation systems can be optimized considering important factors, such as room geometry,outside air conditions and heat and contaminant sources inside the facility [1].

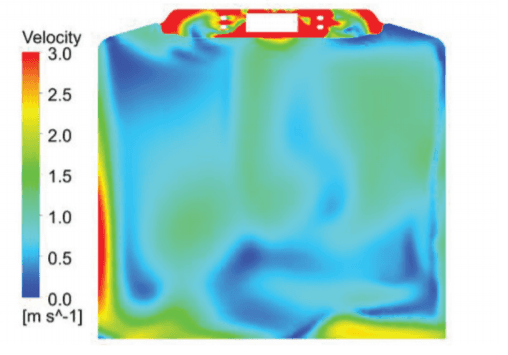

Further utilization of CFD in food processing can be exemplified by design of baking ovens and chillers. The performance of a baking oven can be examined by modeling the airflow inside the oven and the heat and mass transfer around the product. Such models are used to optimize the design of the baking ovens by ensuring proper heat distribution in the oven, thus, the maximum product quality is attained.Similarly, CFD models can be used to predict the temperature distribution and airflow in chillers. In this way, it is possible to design the chiller such that it provides the desired cooling rate fora particular product [2].

Figure 1. Numerical simulation results for the velocity field inside an oven [3].

Several different CFD applications are studied in food processing and apart from optimizing the existing processes, these applications have been helpful for process engineers to design new ones. And as the cost of energy and workforce increased, recent studies are directed towards the processing systems that are available for multiple operations which enables coupling of elementary processes [4]. That provides a remarkable amount of cost efficiency. Another benefit of CFD application to food industry is the quality of the products, where the sterilization processes play a crucial role. CFD enables us to comprehend the food processing mechanisms that govern the physical properties of foods and, thus, can aid the industry to improve the efficiency in sterilization processes [5].

Clearly, CFD is to be a quite helpful tool to understand the physics of existing processing operations and to design new processes and equipment. Although its benefits in the long run are broadly agreed upon, considering the required investments, such as personnel time,necessary code and hardware, many companies are uncertain whether itis a worthy investment currently. Sub-contracting the initial works to CFD expert research organizations could be a reasonable action to overcome the short-term challenges. Also, Simulstore offers various engineering apps, such as y+ calculator and heat sealing, that could be helpful to conduct CFD simulations and optimize othermanufacturing processes used in the food industry. To conclude, it is shown how beneficial CFD can be for the food companies, now it rests upon their decision to invest therein.

References

[1] D.-W. Sun, Computational Fluid Dynamics in Food Processing, Boca Raton, FL: CRC Press, 2007.

[2] G. Scott and P. Richardson, "The Application of Computational Fluid Dynamics in the Food Industry," Trends in Food Science & Technology, vol. 8, no. 4, pp. 119-124, 1997.

[3] U. Kokolj, L. Skerget and J. Ravnik, "The Validation of Numerical Methodology for Oven Design Optimization Using Numerical Simulations and Baking Experiments," Strojniški vestnik - Journal of Mechanical Engineering, vol. 63, no. 4, pp. 215-224, 2017.

[4] "The triplet ‘‘molecular processes–product–process’’ engineering: the future of chemical engineering?," Chemical Engineering Science, vol. 57, no. 22-23, pp. 4667-4690, 2002.

[5] J. Welti-Chanes, F. Vergara-Balderas and D. Bermudez-Aguirre, "Transport phenomena in food engineering: basic concepts and advances," Journal of Food Engineering, vol. 67, no. 1-2, pp. 113-128, 2005.